H rubber single-sided synchronous belt design parameters:

The shape of the teeth is British trapezoid teeth, also known as square teeth, which belongs to the heavy transmission design.

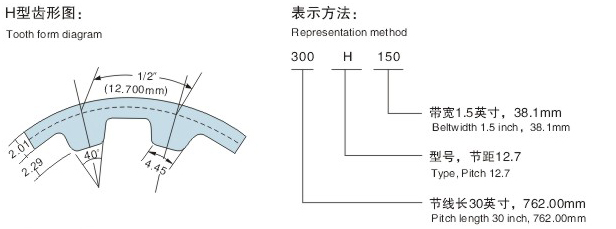

Standard design reference value: Pitch :12.7mm; Tooth height: 2.29mm; Belt thickness: 4.3mm; Angle: 40 degrees

H rubber single-sided synchronous belt design points:

1, H rubber single-sided tooth synchronization belt belongs to the circular control ladder type tooth synchronization belt, tooth shape is trapezoidal teeth.

2, H rubber single-sided tooth synchronization with elastic support and teeth combined with durability and light weight.

3, nylon face to protect and strengthen the tooth surface, increase the wear resistance of H rubber single-sided tooth synchronous belt.

4, H rubber single-sided tooth synchronous belt contains glass fiber long has good stability and flexibility.

H Rubber single-sided synchronous belt identification:

Three parts: Indicates the length, spacing, and width of the belt brought back by the part number. As shown in the following picture. This H rubber single-sided tooth synchronous belt model has a 30 inch (762.00mm) pitch length and a 1.5 inch (38.1mm) bandwidth.

| Specification | Pitch length | Number of teeth | Specification | Pitch length | 齿数 |

| 145 H | 368.30 | 29 | 560 H | 1422.40 | 112 |

| 185 H | 469.90 | 37 | 570 H | 1447.80 | 114 |

| 200 H | 508.00 | 40 | 580 H | 1473.20 | 116 |

| 210 H | 533.40 | 42 | 590 H | 1498.60 | 118 |

| 220 H | 558.80 | 44 | 600 H | 1524.00 | 120 |

| 225 H | 571.50 | 45 | 630 H | 1600.20 | 126 |

| 230 H | 584.20 | 46 | 640 H | 1625.60 | 128 |

| 240 H | 609.60 | 48 | 650 H | 1651.00 | 130 |

| 245 H | 622.30 | 49 | 660 H | 1676.40 | 132 |

| 250 H | 635.00 | 50 | 670 H | 1701.80 | 134 |

| 255 H | 647.70 | 51 | 680 H | 1727.20 | 136 |

| 260 H | 660.40 | 52 | 700 H | 1778.00 | 140 |

| 270 H | 685.80 | 54 | 710 H | 1803.40 | 142 |

| 280 H | 711.20 | 56 | 720 H | 1828.80 | 144 |

| 285 H | 723.90 | 57 | 725 H | 1841.50 | 145 |

| 290 H | 736.60 | 58 | 730 H | 1854.20 | 146 |

| 300 H | 762.00 | 60 | 740 H | 1879.60 | 148 |

| 310 H | 787.40 | 62 | 750 H | 1905.00 | 150 |

| 315 H | 800.10 | 63 | 760 H | 1930.40 | 152 |

| 320 H | 812.80 | 64 | 770 H | 1955.80 | 154 |

| 330 H | 838.20 | 66 | 780 H | 1981.20 | 156 |

| 340 H | 863.60 | 68 | 800 H | 2032.00 | 160 |

| 345 H | 876.30 | 69 | 810 H | 2032.00 | 162 |

| 350 H | 889.00 | 70 | 830 H | 2108.20 | 166 |

| 360 H | 914.40 | 72 | 840 H | 2133.60 | 168 |

| 365 H | 927.10 | 73 | 850 H | 2159.00 | 170 |

| 370 H | 939.80 | 74 | 870 H | 2209.80 | 174 |

| 375 H | 952.50 | 75 | 880 H | 2235.20 | 176 |

| 380 H | 965.50 | 76 | 900 H | 2286.00 | 180 |

| 385 H | 977.90 | 77 | 940 H | 2387.60 | 188 |

| 390 H | 990.60 | 78 | 950 H | 2413.00 | 190 |

| 395 H | 1003.30 | 79 | 960 H | 2438.40 | 192 |

| 400 H | 1016.00 | 80 | 980 H | 2489.20 | 196 |

| 405 H | 1028.70 | 81 | 1000 H | 2540.00 | 200 |

| 410 H | 1041.40 | 82 | 1020 H | 2590.80 | 204 |

| 420 H | 1066.80 | 84 | 1050 H | 2667.00 | 210 |

| 425 H | 1079.50 | 85 | 1070 H | 2717.80 | 214 |

| 430 H | 1092.20 | 86 | 1100 H | 2794.00 | 220 |

| 435 H | 1104.90 | 87 | 1120 H | 2844.80 | 224 |

| 440 H | 1117.60 | 88 | 1130 H | 2870.20 | 226 |

| 445 H | 1130.30 | 89 | 1140 H | 2895.60 | 228 |

| 450 H | 1143.00 | 90 | 1150 H | 2921.00 | 230 |

| 460 H | 1168.40 | 92 | 1160 H | 2946.40 | 232 |

| 465 H | 1181.10 | 93 | 1180 H | 2997.20 | 236 |

| 470 H | 1193.80 | 94 | 1200 H | 3048.00 | 240 |

| 480 H | 1219.20 | 96 | 1250 H | 3175.00 | 250 |

| 485 H | 1231.90 | 97 | 1325 H | 3365.50 | 265 |

| 490 H | 1244.60 | 98 | 1350 H | 3429.00 | 270 |

| 500 H | 1270.00 | 100 | 1400 H | 2556.00 | 280 |

| 510 H | 1295.40 | 102 | 1450 H | 3683.00 | 290 |

| 515 H | 1308.10 | 103 | 1560 H | 3962.40 | 312 |

| 520 H | 1320.80 | 104 | 1600 H | 4064.00 | 320 |

| 525 H | 1333.50 | 105 | 1630 H | 4140.20 | 326 |

| 530 H | 1346.20 | 106 | 1700 H | 4318.00 | 340 |

| 540 H | 1371.60 | 108 | 2200 H | 5588.00 | 440 |

| 550 H | 1397.00 | 110 |